Product Information

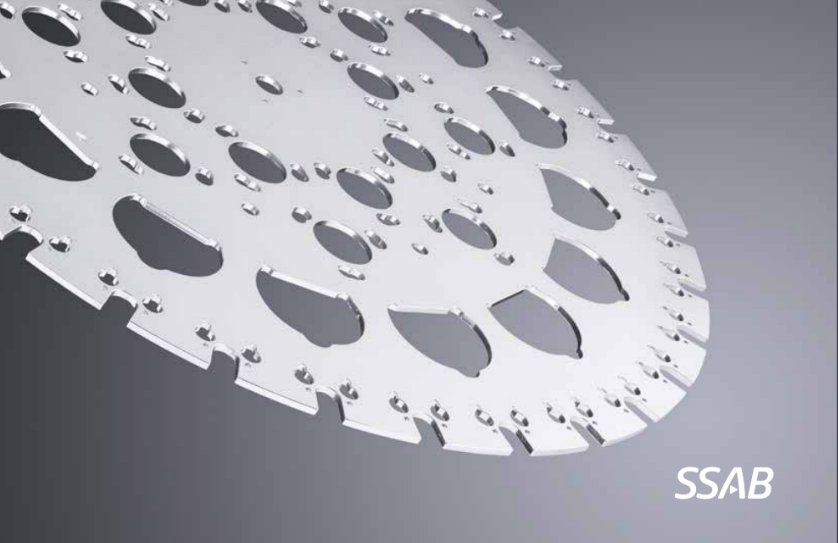

What is Coen’s Steel Laser Steel

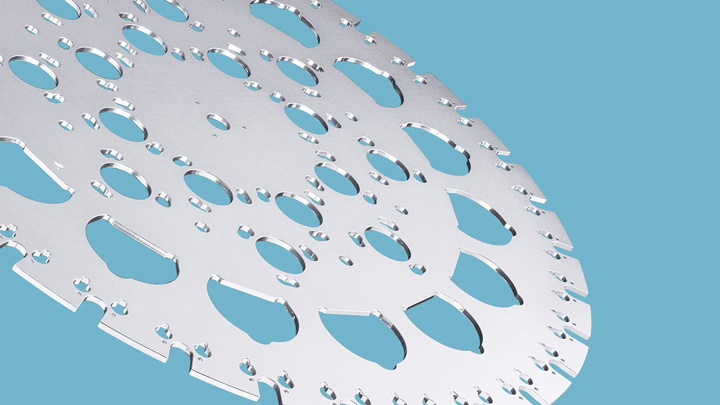

Coen’s Steel Laser Steel is an advanced steel directed to automated production, offering superior properties for Laser cutting, stamping and cold forming.

Ask yourself this:

- Have you steel warping on your Laser bed while cutting causing stoppages during day and night shifts?

- Have you cut parts twisted after laser cutting?

- Have you poor surface steel being supplied by some suppliers causing cutting issues?

- Have you parts cracking when cold forming?

- Its time you tried Coen’s Steel Laser Steel to see what all the fuss is about.

Features & Benefits

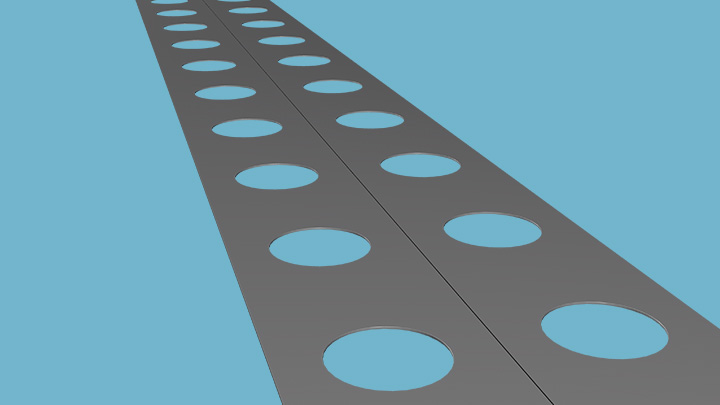

Guaranteed flatness of ≤ 3mm/m, even after cutting

Coen’s Steel Laser Steel comes with guaranteed maximum flatness deviation of 3.0 mm/m, both before and after laser cutting. Our comprehensive process control during its production results in total flat and uniform steel sheets and plates.

Advantages include:

- Making your automated production trouble-free

- Tight nesting for better material utilization

- Reduced need for re-levelling

- Increased dimensional precision of laser-cut components

- Increased yields (i.e., greatly reduced scrap)

- Faster cutting speeds

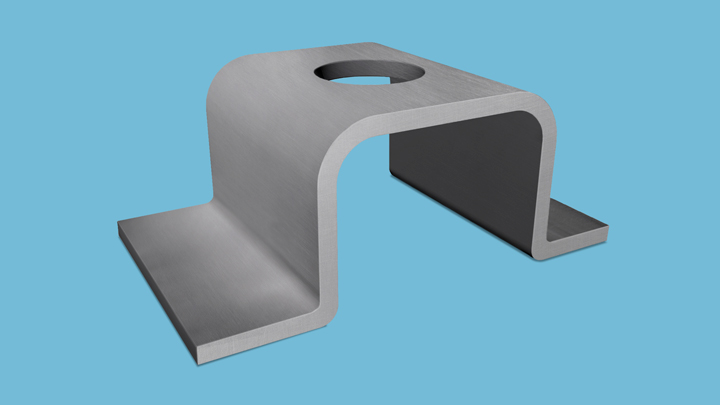

Superior cold-forming properties

Coen’s Steel Laser Steel offers extremely tight bending radiuses in both directions. Consistent mechanical properties and narrow tolerances for all Coen’s Steel Laser Steel guarantee predictable performance with high repeatability for your cold-forming operations.

Advantages include:

- More efficient nesting independent of rolling direction

- Greater freedom in component geometry

- Crack-free bending and trouble-free automated forming

- Increased yield-to-scrap ratios

- Achieve complex shapes without welding

Optimised surface and high-quality cut edges

Coen’s Steel Laser Steel has an optimised surface quality for laser cutting. This allows to maintain the cutting parameters from batch to batch without compromising cut edge quality or precision – even with plates that are 30 mm thick.

Advantages include:

- Trouble-free laser cutting

- Minimized disturbances during production

- Shorter production times

- Less rework

- Higher quality laser-cut components